-

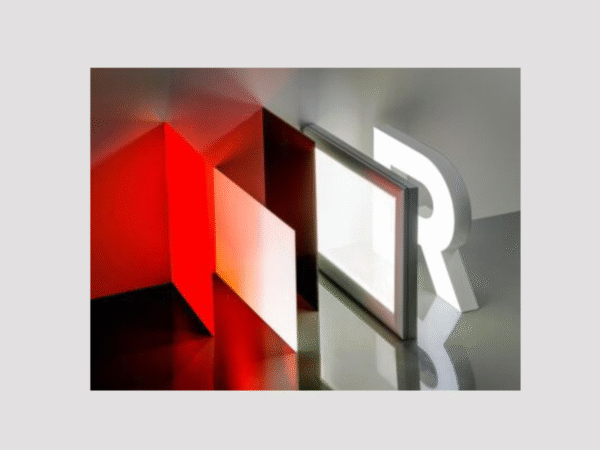

PLEXIGLAS® LED

Maximum transmission for magical lighting

The new dimension of light: specialty PMMA sheets for efficient lighting applications combined with LEDs. Specialty products for edge lighting, side lighting and backlighting offer maximum light transmission without disturbing hot spots, as well as attractive color play effects.

-

PLEXIGLAS® OPTICAL

PLEXIGLAS® Optical hard coated (HC)

PMMA sheets with optical functionalities, high light guidance and distribution provide a uniformly bright and perfectly sharp picture, especially in display applications.

The one-side surface treatment of PLEXIGLAS® Optical hard coated (HC) offers excellent resistance to abrasion and chemicals. -

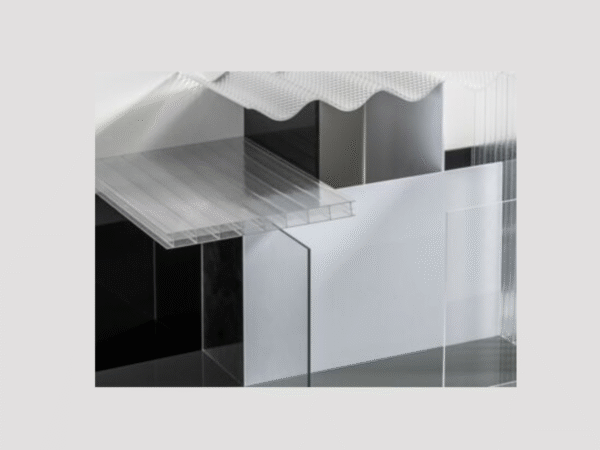

PLEXIGLAS® proTerra

Recycled acrylic glass as the base, proven brand quality as the result

PLEXIGLAS® proTerra products consist of approx. 90 percent reused raw materials and impress with the proven brand quality of the original by POLYVANTIS:

- very resistant to weather and aging

- stronger and lighter than glass in comparable geometries

- easy and versatile to process and very easy to glue together

PLEXIGLAS® proTerra is a sustainably produced, high-quality acrylic. The environmentally friendly material is available as a transparent, opaque black/white or translucent white solid sheet, which can have a glossy finish on both sides or a matte surface on one side depending on the variant. PLEXIGLAS® proTerra is also available as a multi-skin sheet and a corrugated sheet.

Original PLEXIGLAS® is very easy to recycle. To produce PLEXIGLAS® proTerra solid sheets, the recycled raw material is extruded as a sheet core via a co-extrusion process and refined with outer layers of virgin PMMA. The recycled acrylic glass is impermeable to UV radiation, has a gloss surface on both sides and, as a co-extruded material, features the same properties as PLEXIGLAS® XT.

PLEXIGLAS® proTerra multi-skin and corrugated sheets are highly translucent and permanently weather resistant. The sheets are made of impact-modified acrylic with an increased share of recycled PLEXIGLAS® raw materials. The materials offer protection against excessive UV radiation, are hail-proof and highly UV resistant and are guaranteed not to yellow even after 30 years.

PLEXIGLAS® proTerra is a product alternative for all applications in which conserving resources is an important factor, including in designing luminaires and illuminated advertising, in exhibition booth and store fixtures, roofs, wind protection and privacy screens.

However, PLEXIGLAS® proTerra is not the only sustainable product – read on to discover how our other PLEXIGLAS® products also help find solutions for the challenges we face today:

-

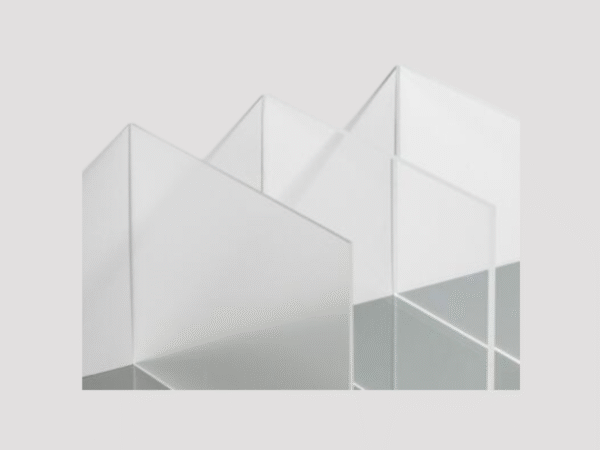

PLEXIGLAS® RESIST

These impact-modified multi-skin, corrugated and solid sheets and tubes combine toughness with excellent weather resistance

-

PLEXIGLAS® SATINICE

This material’s velvet surfaces are robust, pleasant to the touch and discretely light-diffusing.

Sheets and tubes are available with a matte satin surface on one or both sides, or with diffuser beads evenly distributed throughout the material, in various colors. -

PLEXIGLAS® SOLAR

These ultra-pure sheets have specific light transmission properties and high resistance to UV light and weathering, which makes them suitable for high-efficiency solar modules.

PLEXIGLAS® Solar meets the minimum requirements of international standard IEC 62108 for Design Qualification and Type Approval of CPV Modules and Assemblies. -

PLEXIGLAS® SOUNDSTOP

Protection against noise and wind

Original PLEXIGLAS® displays its strengths not only in terms of aesthetics, but also when it comes to acoustics. PLEXIGLAS® Soundstop is a special product that protects against noise and is also used on bridges as effective protection against wind.

Solid PLEXIGLAS® Soundstop sheets feature outstanding airborne sound insulation properties while also offering the highest degree of transparency. This transparency remains intact for a very long period of time. We guarantee that PLEXIGLAS® Soundstop will display virtually no signs of yellowing even after 30 years of permanent use.

In addition, PLEXIGLAS® Soundstop sheets

- offer a diverse range of design options,

- are extremely resistant to weather and aging,

- are stronger and lighter than glass in comparable geometries, and

- are easy and versatile to form and process.

PLEXIGLAS® Soundstop is used for noise and wind protection screens along traffic routes, enclosures and bridges. In order to satisfy a wide range of requirements, the innovative sheets are available in various visually appealing varieties and with special properties, such as:

PLEXIGLAS® Soundstop XT BirdGuard reliably protects against birds, while also providing maximum transparency. This variety features 2 mm-wide black or white strips spaced 30 mm apart, which are perceived as a visible obstacle by birds. Because the strips are embedded within the material, they cannot be washed away by cleaning agents or graffiti removers.

PLEXIGLAS® Soundstop GS CC also provides integrated shatter protection thanks to the embedded polyamide threads. These threads bind together the fragments and prevent them falling in the event that a sheet is broken. PLEXIGLAS® Soundstop GS CC is approved around the world for use as a transparent material for noise protection walls on bridges without additional nets.

-

PLEXIGLAS® SOUNDSTOP SILENTVIEW

PLEXIGLAS® Soundstop SilentView is a transparent noise absorbing system consisting of an aluminium frame and a 30° angled transparent PLEXIGLAS® Soundstop sheet. This innovative design allows incoming noise to be reflected upward towards the horizontal noise absorbing part of the element. PLEXIGLAS® Soundstop SilentView is suitable for any noise barrier installation, including highways and high speed railways.

This newly developed system perfectly combines desired transparency with the absorbing properties of a non-transparent noise protection element. PLEXIGLAS® Soundstop SilentView is the only element worldwide which also complies with the new acoustic standards outlined in EN 1793-5 and EN 1793-6 “Road Traffic Noise reducing devices – test method for determining the acoustic performance using in situ values of sound reflection (1793-5) and airborne sound insulation (1793-6) under direct sound field conditions.”

While focused on new Noise Barrier installations, PLEXIGLAS® Soundstop SilentView is ideal for replacing old, unsightly, or defective elements quite easily. The existing infrastructure can be re-used without additional construction costs.

-

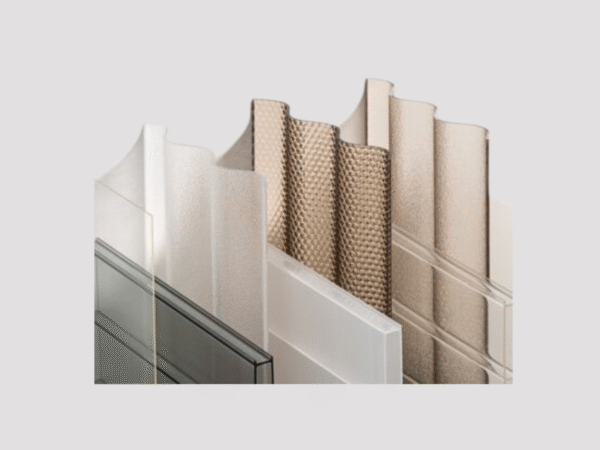

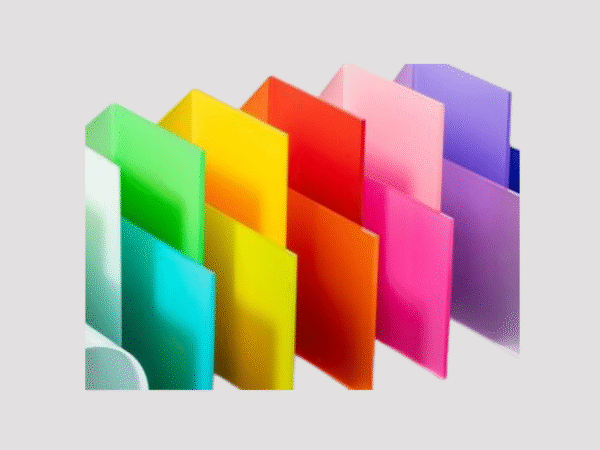

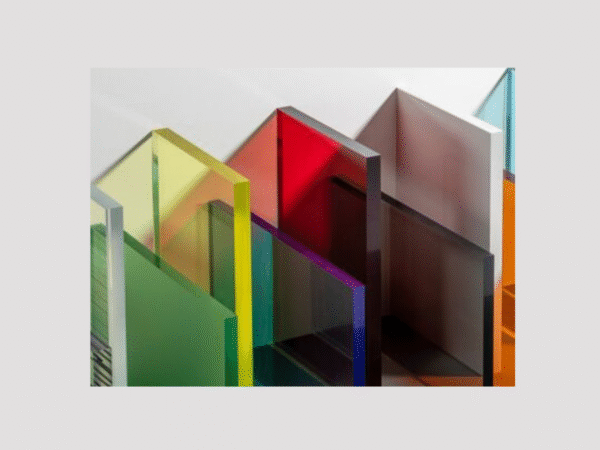

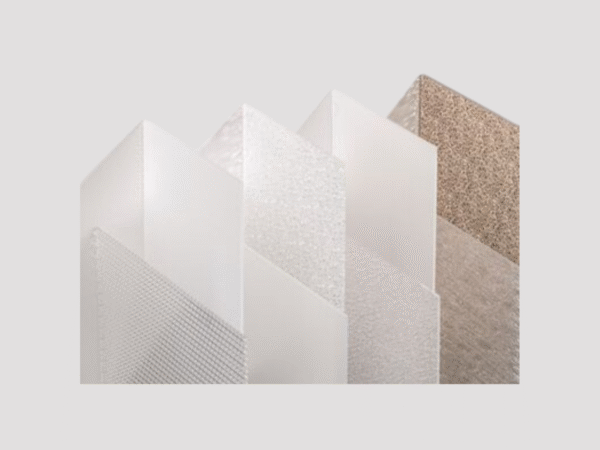

PLEXIGLAS® TEXTURES

Diverse surface structures and design

Original PLEXIGLAS® offers a wide range of solid sheets with different surfaces and haptic pattern.

Corrugated, with comb or in bark optic – PLEXIGLAS® Textures makes it possible.

Our brand product is also available in different colors. -

SECURITY & ID CARD FILMS

Fraud, identity theft and counterfeiting call increasingly for constant vigilance and innovation in electronic ID cards, and so consequently accelerating the demand for more safety features to protect ID cards and security documents. The challenge is to incorporate these sophisticated security features into the latest electronic ID cards while offering thinner individual card layers – down to 50 microns or less – to construct them with high durability and all while maintaining ease of manufacturing.

POLYVANTIS offers a high-performance polycarbonate LEXAN™ SD film portfolio specially designed for electronic ID cards, government, military and police ID cards, passport data pages, green cards, border crossing cards and driver’s licenses. LEXAN Secure ID film portfolio includes a clear lasermarkable layer, co-extruded layers, a bright white core layer, flexible coated overlays and a clear overlay grades for the cover or intermediate layers.

These films deliver tight gauge tolerances to simplify manufacturing of cards within mandated thickness parameters providing our customers significantly higher productivity. Thanks to the low and controlled shrinkage of LEXAN films, Smart card, passport and ID card manufacturers can use heat and pressure to join all layers together to form a card that cannot be pulled apart, preventing risk for disassembly, helping not only to extend the card’s service life but also better protect security features inside it. They also provide high performance, exceptional durability and resistance to abrasive cleaning agents and to the chemicals found in sun creams, cosmetics, oils, greases and fuels.